-

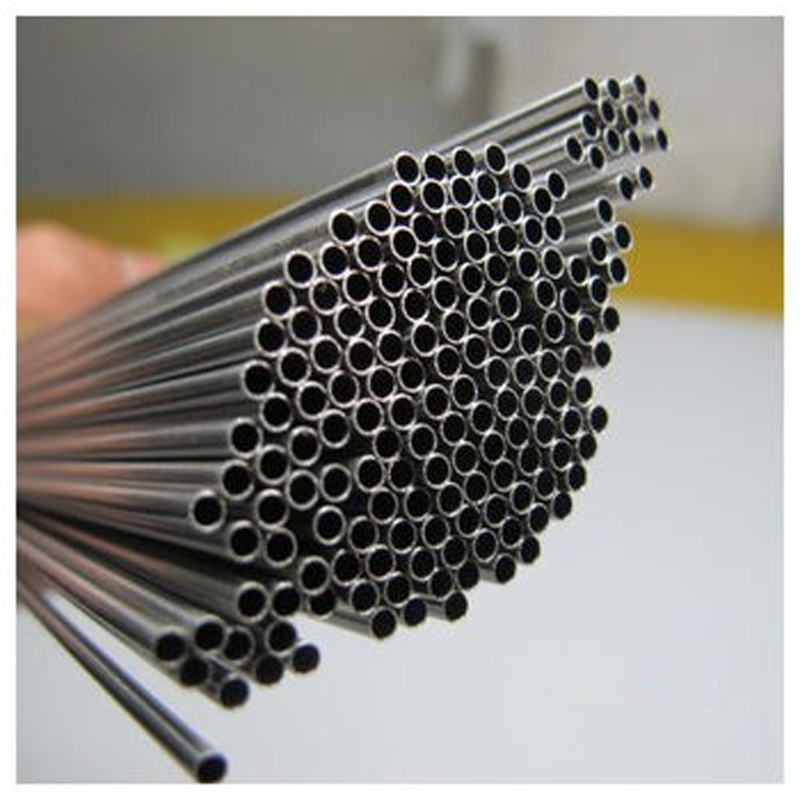

13CrMo4-5 ND Alloy Steel enweghị nkebi Pipe

09CrCuSb (ND) tube nchara enweghị nkebi maka sulfuric acid nguzogide, ebe igirigi dị ala na corrosion

ND ígwè bụ ụdị ọhụrụ nke obere alloy structural steel, ma e jiri ya tụnyere ígwè ndị ọzọ, dị ka obere carbon ígwè, Corten, CRIA, ND ígwè nwere uru nke magburu onwe corrosion iguzogide na ígwè onwunwe.Nsonaazụ nnwale gosiri na nguzogide corrosion nke ND ígwè n'ime mmiri mmiri dị ka sulfuric acid, hydrochloric acid na sodium chloride dị elu karịa ígwè carbon.Ihe kachasị pụta ìhè bụ ikike nke sulfuric acid igirigi iguzogide ihe mgbochi;The n'ibu onwunwe dị elu na kwụsie ike karịa carbon ígwè si ụlọ okpomọkụ na 500 C, na ịgbado ọkụ arụmọrụ isnice.ND ígwè mgbe niile eji maka nrụpụta economizer, okpomọkụ Exchanger, ikuku pre-heater, ebe 1990, ND ígwè e ọtụtụ ebe na-eji na ụlọ ọrụ nke petrifaction na ọkụ eletrik.

-

Lelee Valve, Valve na-ebelata nrụgide, Valve Drain, Valve akụrụngwa

valvụ bụ ihe na-achịkwa n'ime usoro nnyefe mmiri, na-arụ ọrụ nke ịkpụpụ, nhazi, ntụgharị, na-egbochi nkwụsị, nkwụsị nrụgide, ntụgharị ma ọ bụ nkwụsị nrụgide.

A na-eji Valvalve na sistemụ njikwa mmiri, site na valvụ nkwụsị kachasị mfe ruo na sistemụ njikwa akpaka dị mgbagwoju anya, ụdị ya na nkọwapụta ya dị iche iche.Enwere ike iji valvụ chịkwaa ụdị mmiri dị iche iche dị ka ikuku, mmiri, uzuoku, mgbasa ozi na-emebi emebi dị iche iche, apịtị, mmanụ, igwe mmiri na mgbasa ozi redioaktivu.Dị ka ihe onwunwe si kwuo, a na-ekewakwa valvụ ahụ na nkedo ígwè nkedo, nkedo ígwè valves, igwe anaghị agba nchara (201,304,316, wdg), chromium molybdenum ígwè valves, chromium molybdenum vanadium ígwè valves, abụọ-phase ígwè valves, plastic valves, non - ọkọlọtọ ahaziri valvụ, wdg.

-

A214 A178 A423 A53 ọkpọkọ kwụ ọtọ kwụ ọtọ, ERW, Spiral Welded Pipe

Ngosipụta ngwaahịa:

A na-ejikarị igwe anaghị agba nchara welded ọkpọkọ na mmanụ ala, ụlọ ọrụ kemịkalụ, ọgwụ, nri, ụgbọ mmiri, nchekwa gburugburu ebe obibi na mpaghara ndị ọzọ.A na-eji eriri igwe anaghị agba nchara, nwere oke okpomọkụ na-eguzogide, nguzogide corrosion, nrụgide nrụgide siri ike na njirimara ndị ọzọ.

-

Flange Welding Flange / Welding Neck Flange/ Flange Screwed

Ngosipụta ngwaahịa:

Njikọ flange ịgbado ọkụ bụ itinye ọkpọkọ abụọ, ọkpọkọ ma ọ bụ akụrụngwa, nke mbụ nke ọ bụla edobere na ịgbado ọkụ.N'etiti weld abụọ ahụ, gbakwunyere flanged pads, jikọtara ya na bolting iji mechaa njikọ ahụ.Welding bụ ọnọdụ njikọ dị mkpa maka ịrụ ọrụ pipeline dị elu.Njikọ flange ịgbado ọkụ dị mfe iji ma nwee ike idi nnukwu nrụgide.

-

304, 310S, 316, 347, 2205 Igwe anaghị agba nchara

Ngosipụta ngwaahịa:

Igwe anaghị agba nchara n'akuku ígwè, nke bụ a nri Angle ígwè perpendicular ọ bụla ọzọ.Ọ bụ ígwè e mere n'akụkụ aka nri n'akụkụ atọ na akụkụ na ala.A na-ejikarị igwe anaghị agba nchara na-ekpo ọkụ na-ekpo ọkụ ma ọ bụ na-ehulata oyi, ogologo na nha nke Angle Angle nwere ike ịhazi dị ka mkpa dị, na mmepụta usoro n'ozuzu na-agụnye ọkụ na-agbagharị agbagharị na oyi na-atụ nhazi.Igwe igwe na-ekpo ọkụ na-ekpo ọkụ na-ezo aka na kpo oku billet na okpomọkụ ụfọdụ site na okporo ụzọ na-atụgharị mgbe ịpịrị na akpụ.Nhazi na-ehulata oyi site na igwe iji mepụta efere ígwè pretreatment.Dị ka ọdịdị ahụ si dị, enwere ike kewaa ya n'akụkụ nha anya na akụkụ ndị na-adịghị mma, nke nwere ike ịmepụta usoro nrụgide dị iche iche ma ọ bụ dị ka njikọ njikọ, nke a na-ejikarị eme ihe n'ọtụtụ dị iche iche nke ihe owuwu nke oge a, ma bụrụ ihe dị mkpa na ihe dị mkpa na ụlọ ọrụ mmepụta ihe nke oge a.

-

ST37 ST52 S235 JRS275 A36 A53 Channel ígwè

Ngosipụta ngwaahịa:

Trough ígwè bụ uzo ogologo warara ígwè, nke bụ nke carbon structural ígwè maka owuwu na ígwè.Maka akụkụ dị mgbagwoju anya nchara, akụkụ nke akụkụ bụ ụdị uzo.Ogologo na nha nke ọwa ígwè nwere ike ịhazi dịka achọrọ.Usoro mmepụta nke trough ígwè n'ozuzu na-agụnye ikpo ọkụ na-ekpo ọkụ na nhazi ihu oyi.Igwe igwe na-ekpo ọkụ na-agbagharị agbagharị bụ iji kpoo billet ahụ ruo ụfọdụ okpomọkụ.Nhazi na-ehulata oyi site na igwe iji mepụta efere ígwè pretreatment.A na-eji ígwè ọkụ na-ekpo ọkụ na oyi na-ekpo ọkụ mee nchara ọwa.O nwere ngalaba ezumike ma bụrụ ihe a na-ahụkarị maka ọtụtụ ngwaahịa nchara.

-

Carbon ígwè Pipe Fitting A234WPB A420WPL6 ST35.8

Ngosipụta ngwaahịa:

The isi ngwaahịa nke carbon ígwè ọkpọkọ oyiyi akwa na-agụnye carbon ígwè elbow, carbon ígwè flange, carbon ígwè tee, carbon ígwè tee, carbon ígwè pụrụ iche dayameta ọkpọkọ (nnukwu na obere isi), carbon ígwè isi (pipe okpu), wdg The isi mmejuputa iwu. ụkpụrụ gụnyere ọkọlọtọ mba, ọkọlọtọ American, ọkọlọtọ Japanese, wdg, n'ime nke ọkọlọtọ mba gụnyekwara ọkọlọtọ Ministry of Chemical Industry, Sinopec pipe fitting standards, ọkọlọtọ ọkpọkọ ọkụ.Ngwakọta ọkpọkọ carbon ígwè bụ okwu izugbe maka njikọ, njikwa, nnọchi, shunt, akara na ihe nkwado na sistemụ ọkpọkọ.Ngwakọta ọkpọkọ bụ ihe na-ejikọta ọkpọkọ na ọkpọkọ.Ngwunye ọkpọkọ dị elu dị mma maka akụrụngwa uzuoku dị elu, kemịkalụ dị elu nke okpomọkụ na pipeline dị elu, ụlọ ọrụ ike na ihe ọkụkụ nuklia, ngwa ọkụ ọkụ ọkụ ọkụ na ebe ndị ọzọ pụrụ iche.A na-eji akwa ọkpọkọ eme ihe n'ọtụtụ ebe n'ihe owuwu, ụlọ ọrụ kemịkalụ, Ngwuputa, ume na ọtụtụ ngalaba injinia ndị ọzọ.E kwesịghị ileghara ọrụ ya dị mkpa anya.

-

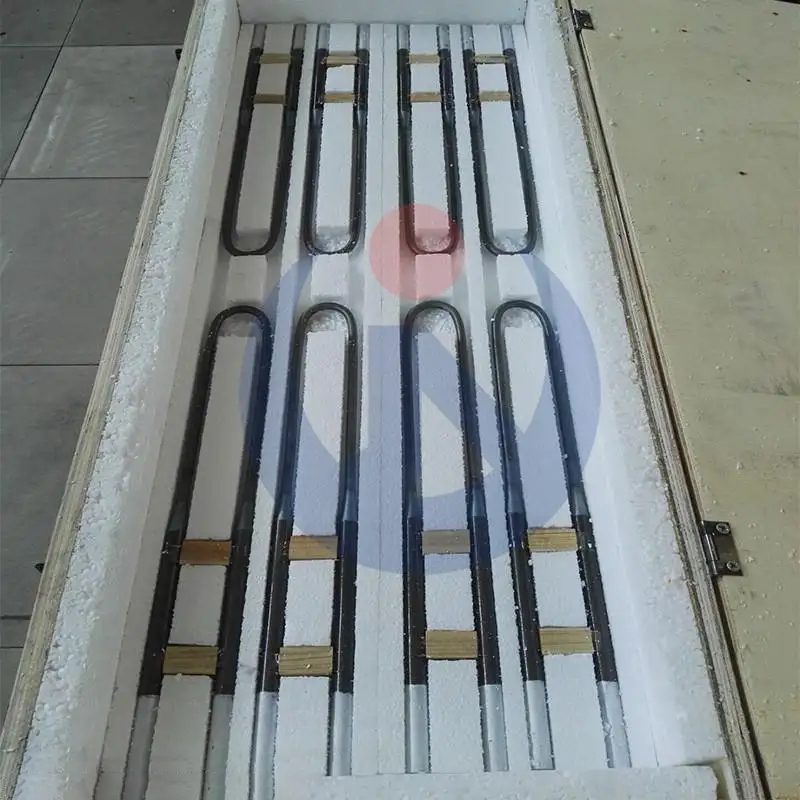

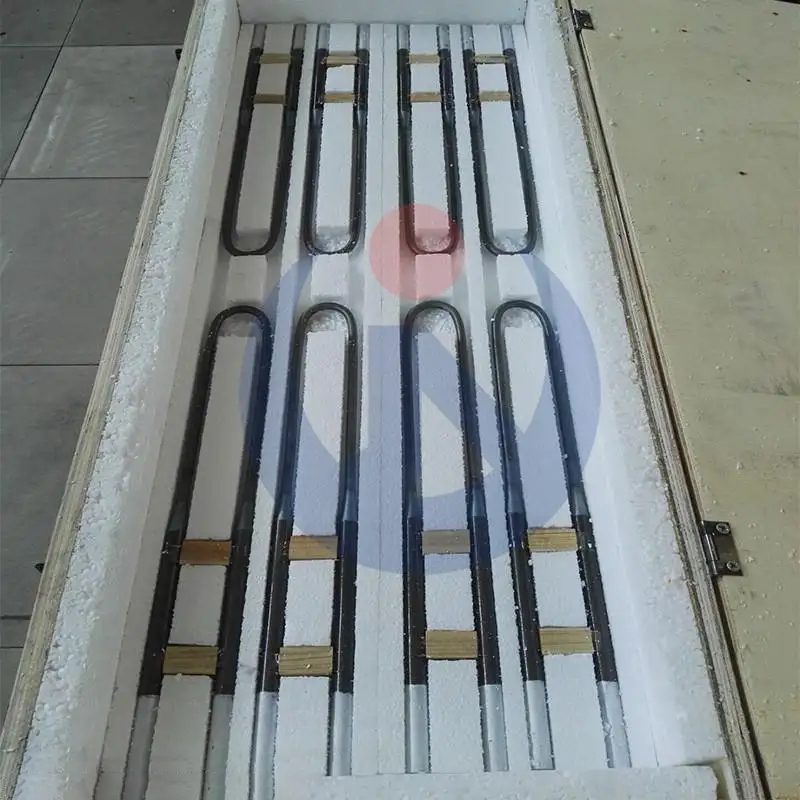

U Tubing Heat Exchanger Tube/ U ehulata tube/okpomọkụ Tube

Ngosipụta ngwaahịa:

'U' na-ehulata site na usoro ọrụ oyi.

A na-ehulata 'U' na radius achọrọ dị ka eserese ndị ahịa si dị.

Akụkụ gbagọrọ agbagọ na ụkwụ inch isii na-ebelata nrụgide site na ikpo ọkụ na-eguzogide.

A na-agafe gas inert (Argon) site na ya n'ogo a chọrọ iji zere oxidation na ID.

A na-enyocha radius maka OD ya na mkparị mgbidi ya na nkọwapụta akwadoro.

A na-enyocha akụrụngwa anụ ahụ na obere ihe n'ọnọdụ atọ dị iche iche.

A na-eji ule Dye Penetrant na-eme nleba anya n'ọhụụ maka waviness na mgbawa.

A na-anwale tube ọ bụla n'ime mmiri na nrụgide akwadoro iji lelee maka ntapu.

A na-eme ule bọọlụ owu iji lelee ịdị ọcha ID nke tube ahụ.

Mgbe nke ahụ gasịrị, a kpọkọtara ya, akpọnwụọ, tinye akara na jupụta.

-

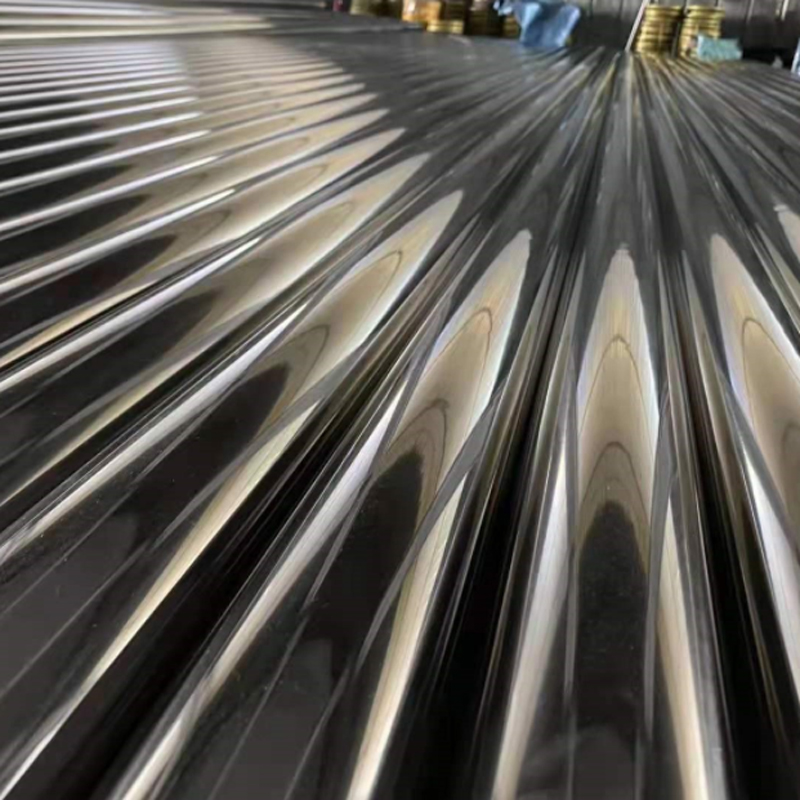

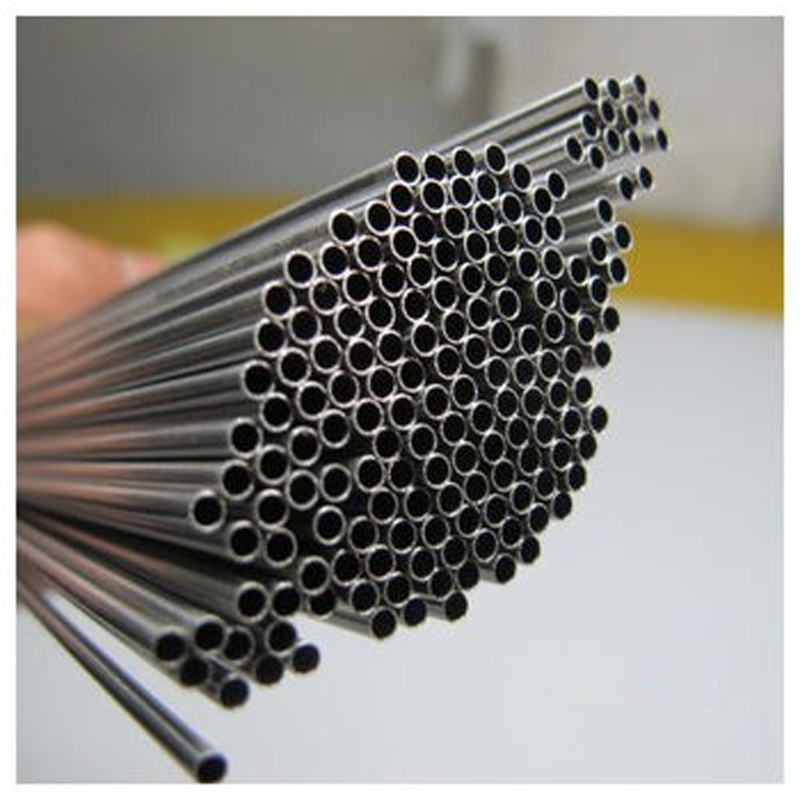

304, 316, 347H, S32205 igwe anaghị agba nchara welded ọkpọkọ/ERW

Ngosipụta ngwaahịa:

Igwe anaghị agba nchara welded ọkpọkọ, zoro aka dị ka ịgbado ọkụ ọkpọkọ, na-ejikarị ígwè ma ọ bụ ígwè eriri site unit na ebu eriri igwe ịkpụzi mgbe ịgbado ọkụ mere nke ígwè anwụrụ.welded ígwè ọkpọkọ mmepụta usoro dị mfe, elu mmepụta arụmọrụ, ọtụtụ iche na nkọwa.

Dị ka ojiji, ọ na-ekewa n'ime izugbe welded ọkpọkọ, okpomọkụ Exchanger ọkpọkọ, condenser pipe, galvanized welded ọkpọkọ, oxygen ịgbado ọkụ ọkpọkọ, waya casing, metric welded ọkpọkọ, idler ọkpọkọ, miri ọma mgbapụta ọkpọkọ, ụgbọala ọkpọkọ, transformer ọkpọkọ, electric. ịgbado ọkụ mkpa mgbidi ọkpọkọ, electric ịgbado ọkụ ọkpọkọ na gburugburu welded ọkpọkọ.

-

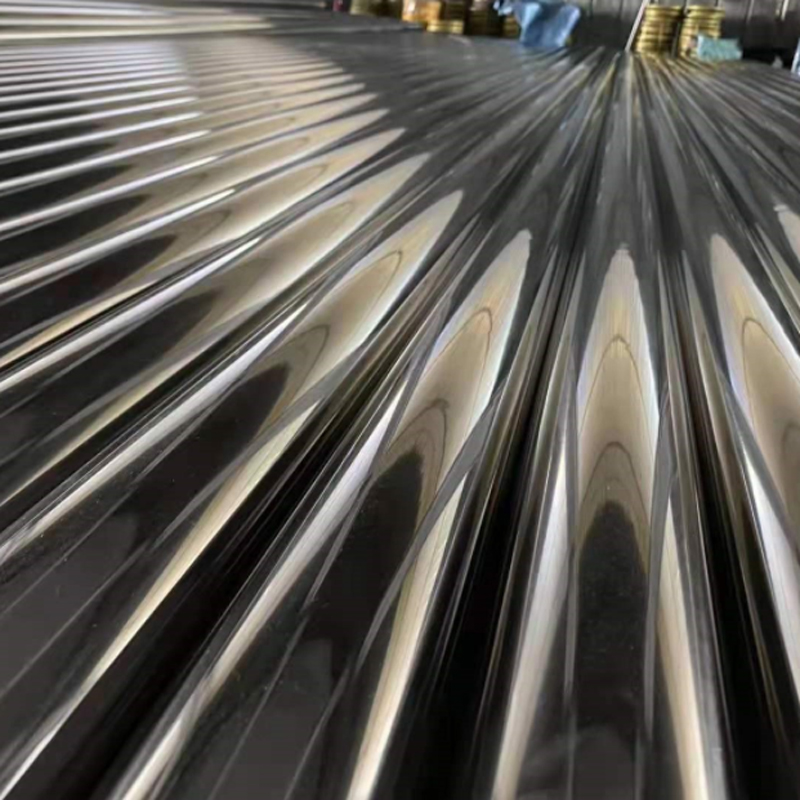

304, 310S, 316L igwe anaghị agba nchara

Ngosipụta ngwaahịa:

Divhot akpọrepu, ọkụ extrusion na oyi ịbịaru (akpọrela) igwe anaghị agba nchara ọkpọkọ dị ka mpịakọta usoro.

Dị ka igwe anaghị agba nchara metallographic nzukọ nke dị iche iche igwe anaghị agba nchara ọkpọkọ, marstenitic igwe anaghị agba nchara, austenitic igwe anaghị agba nchara, austenite-ferric igwe anaghị agba nchara, wdg.

-

A234 WPB SS400 ST35.8 P235GH Carbon Steel Elbow

Ngosipụta ngwaahịa:

Na usoro ọkpọkọ, ikiaka bụ ọkpọkọ dabara adaba nke na-agbanwe ntụzịaka nke ọkpọkọ.Dị ka Angle si kwuo, e nwere atọ a na-ejikarị 45 ° na 90 ° 180, na mgbakwunye na mkpa injinia na ihe ndị ọzọ na-adịghị mma dị ka 60 ° dị ka ọrụ ahụ si dị.Ihe ndị dị n'ikpere aka gụnyere nkedo ígwè, igwe anaghị agba nchara, alloy steel, forgable cast iron, carbon steel, non-ferrous metals and plastics.

Ụzọ nke ijikọ na ọkpọkọ bụ: ịgbado ọkụ ozugbo (ụzọ a na-ejikarị eme ihe) njikọ flange, njikọ ọkụ ọkụ ọkụ, njikọ ọkụ eletrik, njikọ eriri na njikọ nkwụnye, wdg. Dị ka usoro mmepụta ihe si dị, enwere ike kewaa ya n'ime: ịgbado ọkụ. ikiaka, stamping elbow, push elbow, casting elbow, butt welding elbow, etc. Aha ndị ọzọ: gbagọ ogo 90, ehulata aka nri, wdg.

-

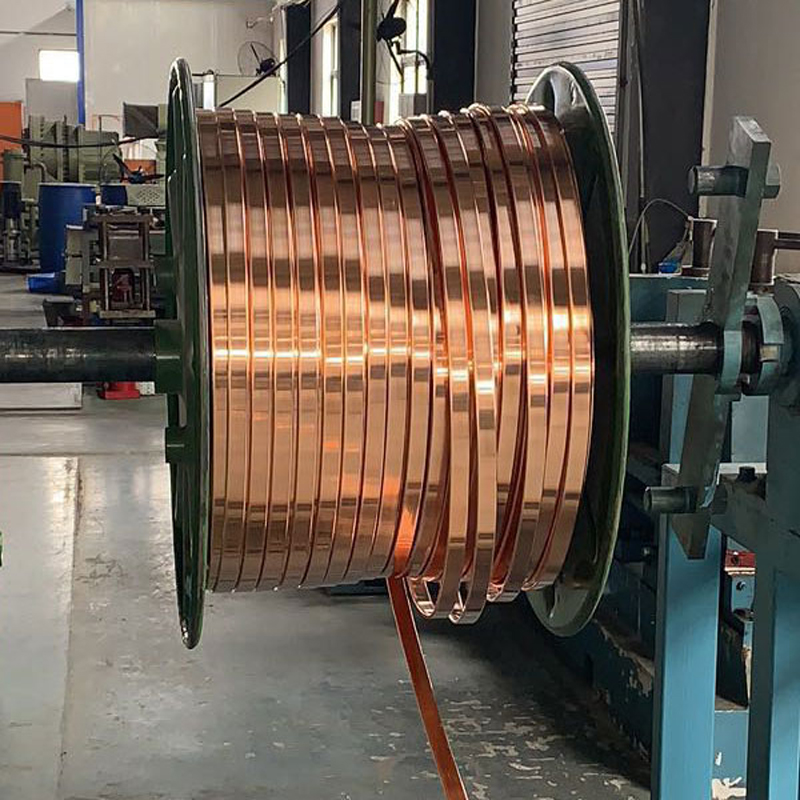

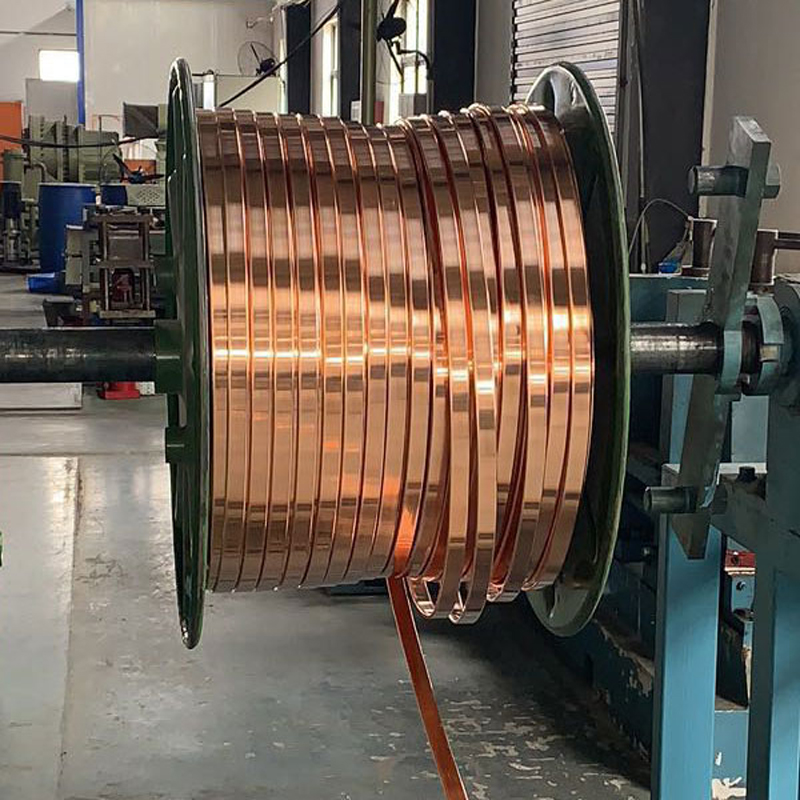

Eriri ọla kọpa, mpempe ọla kọpa, eriri ọla kọpa, efere ọla kọpa

Ngosipụta ngwaahịa:

Ọla ọla ọcha, bụ alloy dabeere na ọla kọpa nwere nickel dị ka isi ihe agbakwunyere, bụ ọcha silvery, nwere ọmarịcha ọla, yabụ aha ọla kọpa ọcha.Ọla kọpa na nickel nwere ike agbaze na ibe ya ruo mgbe ebighị ebi, si otú a na-akpụ a na-aga n'ihu siri ike ngwọta, ya bụ, n'agbanyeghị nkezi nke ibe ya, na mgbe niile α -one-phase alloy.Mgbe a na-ejikọta nickel n'ime ọla kọpa na-acha uhie uhie maka ihe karịrị 16%, ụcha alloy na-esi na ya pụta na-acha ọcha dị ka ọlaọcha, na ọdịnaya nke nickel dị elu, na-achacha agba.Ọdịnaya nke nickel na ọla kọpa ọcha bụ n'ozuzu 25%.