-

Alloy Steel Pipe Fitting A234WP12 P1 PA22 P5

Ngosipụta ngwaahịa:

Alloy Steel Pipe Fittings bụ okwu n'ozuzu nke akụkụ ndị na-ejikọta, ịchịkwa, na-agbanwe agbanwe, na-atụgharị, na-emechi ma na-akwado na usoro ọkpọkọ.Ngwakọta ọkpọkọ bụ akụkụ nke na-ejikọta ọkpọkọ n'ime ọkpọkọ.Ngwunye ọkpọkọ dị elu dabara adaba maka akụrụngwa uzuoku dị elu, kemịkalụ dị elu nke kemịkalụ na pipeline dị elu, ụlọ ọrụ ike na ụgbọ mmiri ike ọkụ nuklia, ngwa ọkụ ọkụ ọkụ ọkụ na ebe ndị ọzọ pụrụ iche.A na-eji akwa ọkpọkọ eme ihe n'ọtụtụ ebe injinia dị ka ihe owuwu, ụlọ ọrụ kemịkalụ, Ngwuputa na ume.E kwesịghị ileghara ọrụ ya dị mkpa anya.

-

Igwe anaghị agba nchara maka ọkpọkọ ọkpọkọ ọkụ

Ngosipụta ngwaahịa:

Ọgwụgwọ okpomọkụ-bụ usoro nke na-eji kpo oku na jụrụ oyi na-agbanwe ihe anụ ahụ nke ọkpọkọ mmiri ọkụ.Ọgwụgwọ okpomọkụ nwere ike imeziwanye microstructure nke tube na-ekpo ọkụ na-ekpo ọkụ, nke mere na iji nweta ihe anụ ahụ chọrọ.Isi ike, isi ike, na nguzogide iyi bụ ọtụtụ ihe ndị e nwetara site na ọgwụgwọ okpomọkụ.Iji nweta njirimara ndị a, jiri quenching & lt na ọgwụgwọ okpomọkụ;na-akpọ quenching & gt;, tempering, annealing & lt;agbaze & gt;na elu hardening, wdg.

-

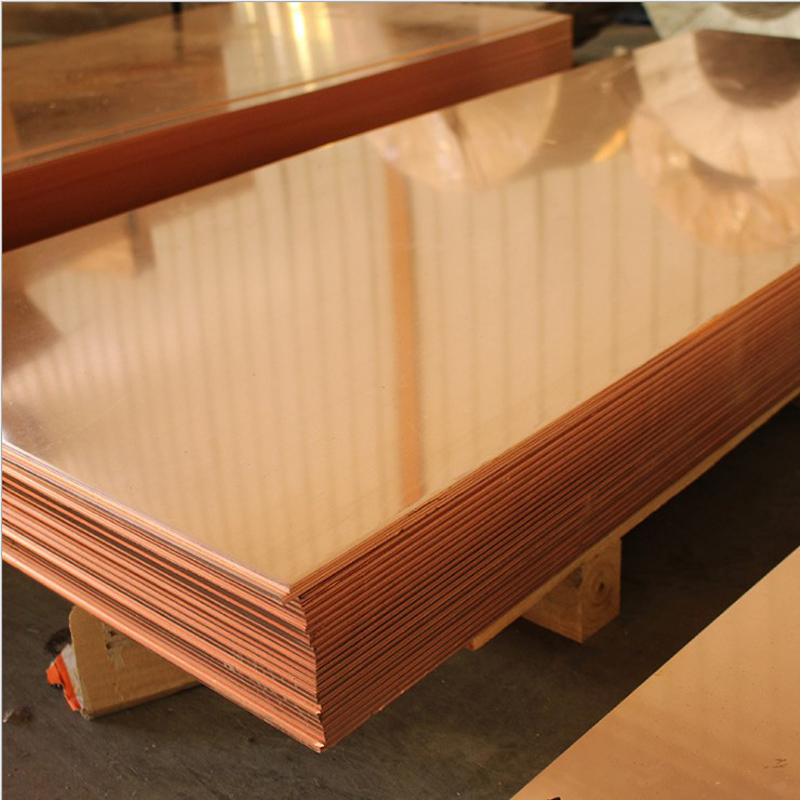

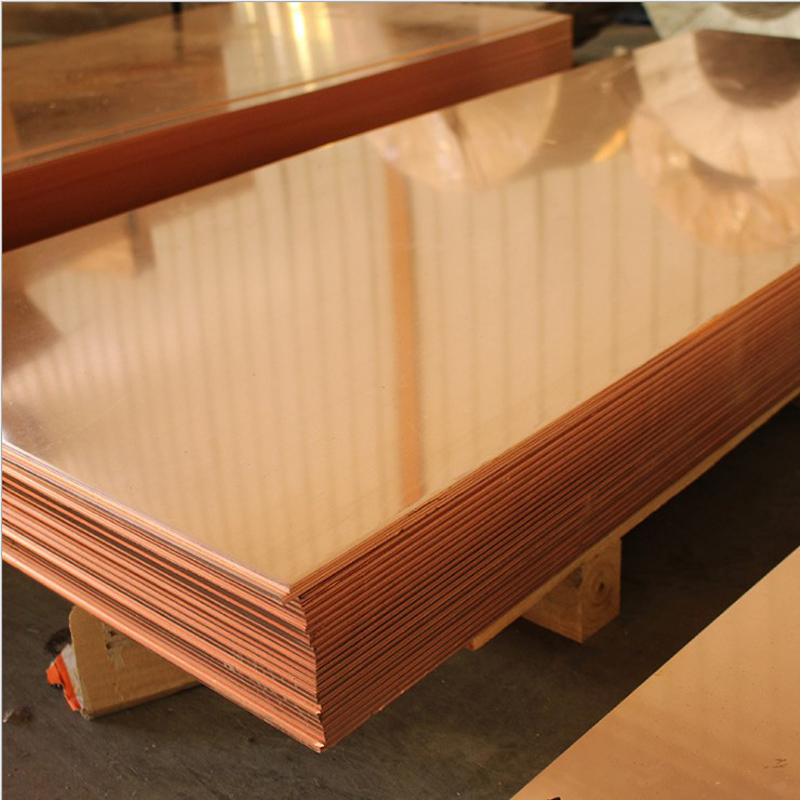

Akwụkwọ mpịakọta ọla, Mpempe ọla kọpa, eriri ọla kọpa, efere ọla kọpa

Ngosipụta ngwaahịa:

Ọla kọpa dị ọcha bụ ọla kọpa nke nwere ọla kọpa kachasị elu, n'ihi na ihe bụ isi bụ ọla kọpa gbakwunyere ọlaọcha, ọdịnaya ya bụ 99.5 ~ 99.95%;isi ihe na-adịghị ọcha: phosphorus, bismuth, antimony, arsenic, iron, nickel, lead, iron, tin, sọlfọ, zinc, oxygen, wdg;eji na-eme ka conductive akụrụngwa, elu ọla kọpa alloy, ọla dabeere alloy.

Enwere ike kewaa ọla kọpa aluminom ụzọ abụọ.Otu na-eme ka ọla kọpa aluminom wepụ ihe ndị na-adịghị ọcha ma mee ka mmiri dịkwuo elu, alloy anaghị agafe 0,5%;nke ọzọ bụ forging brass aluminom na-amụba corrosion eguzogide, a na-ejikarị dị ka condensing ọkpọkọ, n'ozuzu mejupụtara nso bụ Al1 ~ 6%, Zn 24 ~ 42%, na Cu 55 ~ 71%.

-

Ọkụ na-ekpo ọkụ Finned Tube

Ngosipụta ngwaahịa:

Wing tube okpomọkụ Exchanger bụ tubular okpomọkụ Exchanger nwere nku, nke nwere ike mejupụtara otu ma ọ bụ ọtụtụ fin tubes nwere ike inwe shei ma ọ bụ shei.Ọ bụ ihe na-ekpo ọkụ na-ekpo ọkụ ọhụrụ kwesịrị ekwesị maka mmiri mmiri gas na mmiri mmiri nke nwere ike ịhazi dịka ọnọdụ paramita;fin tube bụ isi akụkụ nke fin okpomọkụ Exchanger.Iji mee ka ọkụ ọkụ na-eme ka ọ dịkwuo mma, a na-agbakwụnye nku n'elu ikpo ọkụ ọkụ ọkụ, ka ọ na-eme ka ebe dị n'èzí nke tube na-ekpo ọkụ na-ekpo ọkụ, iji nweta nzube nke imeziwanye ọkụ ọkụ ọkụ.

-

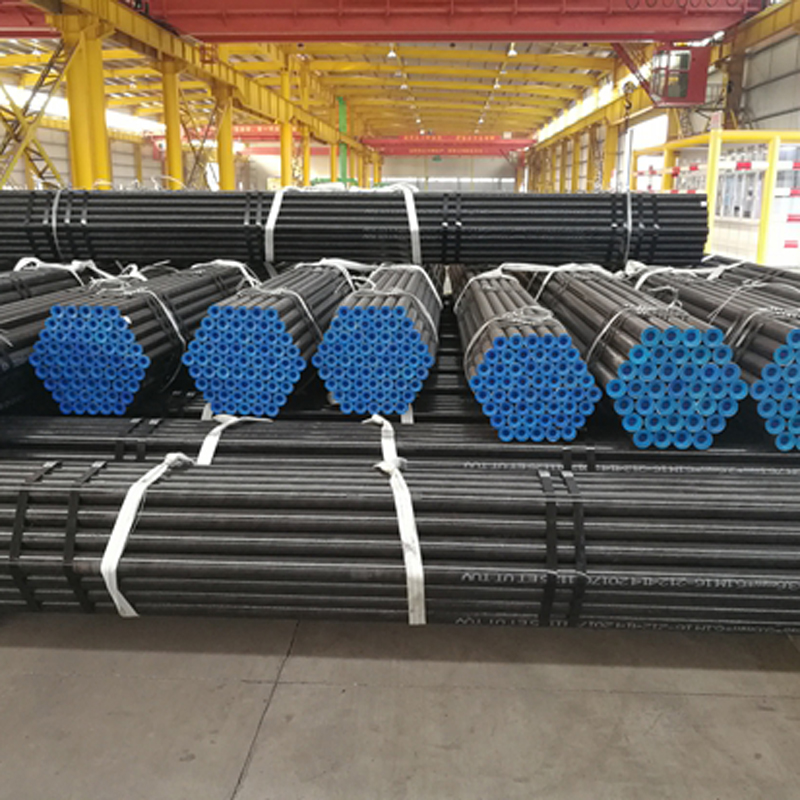

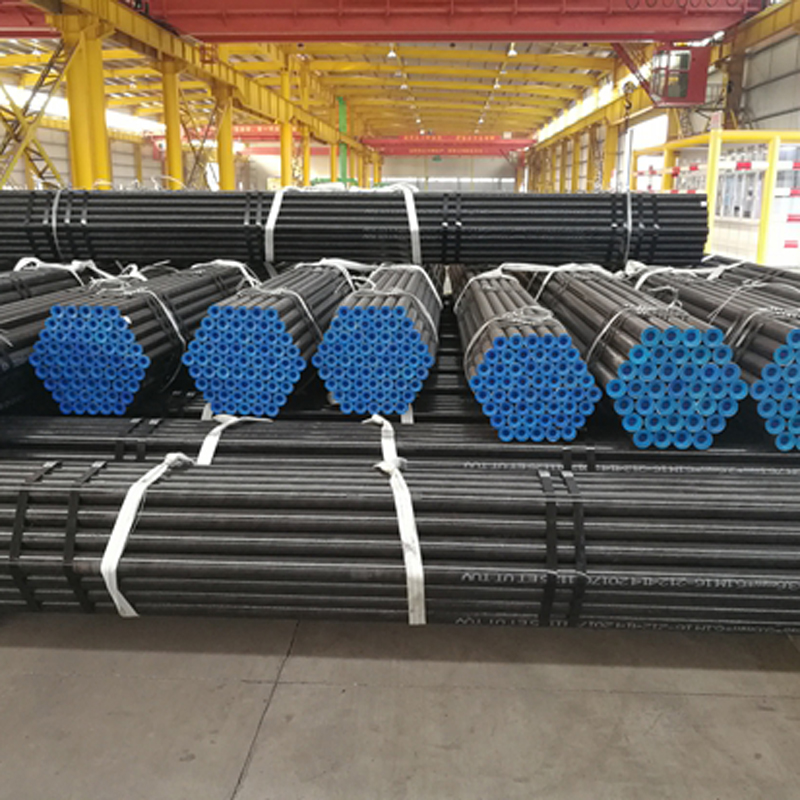

P235GH ST35.8 SA192 Carbon Steel enweghị nkebi Pipe / Igwe ọkụ Tube

Ngosipụta ngwaahịa:

Ọkpụkpọ ọkpọkọ bụ ụdị ọkpọkọ enweghị nkebi.Usoro mmepụta ihe bụ otu ihe ahụ dị ka ọkpọkọ na-enweghị ihe ọ bụla, ma e nwere ihe siri ike chọrọ maka ụdị ígwè eji eme ihe maka ịmepụta ọkpọkọ ígwè.Dị ka okpomọkụ nke ojiji, ọ na-ekewa n'ime izugbe ji esi mmiri ọkụ ọkpọkọ na elu mgbali ọkpọkọ.

-

T11 T12 T22 T91 T92 Alloy Steel enweghị nkebi Pipe

Ngosipụta ngwaahịa:

Alloy enweghị nkebi nchara ọkpọkọ bụ ụdị nke enweghị nkebi ígwè ọkpọkọ, ya arụmọrụ dị nnọọ elu karịa n'ozuzu enweghị nkebi ọkpọkọ, n'ihi na ụdị ígwè ọkpọkọ nwere Cr ntụnyere.

Ọtụtụ ndị, ya elu okpomọkụ nguzogide, ala okpomọkụ na-eguzogide, corrosion eguzogide ịrụ ọrụ adịghị atụnyere ndị ọzọ enweghị nkebi ígwè ọkpọkọ, otú alloy pipe na mmanụ, chemical ụlọ ọrụ, ọkụ eletrik, ji esi mmiri ọkụ na ndị ọzọ na ụlọ ọrụ na-ọtụtụ ebe.

Alloy enweghị nkebi ígwè ọkpọkọ nwere ihe ndị dị ka silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminum, ọla kọpa, boron, obere ụwa na na.

-

Efere ọla kọpa, mpempe ọla kọpa, eriri ọla kọpa

Ngosipụta ngwaahịa:

Akpụkpọ anụ:

Alloy ọla kọpa nwere nickel dị ka isi ihe agbakwunyere.Ọla kọpa nickel ọnụọgụ abụọ alloy na-akpọ nkịtị ọcha ọla kọpa na manganese zinc aluminum na ndị ọzọ ọcha ọla kọpa alloy na-akpọ mgbagwoju ọcha ọla kọpa.A na-ekewa ọla kọpa na-acha ọcha nke ụlọ ọrụ n'ime nhazi ọcha ọla kọpa na eletriki ọcha ọla kọpa abụọ edemede.A na-eji ọla kọpa na-acha ọcha arụ ọrụ mara ezigbo ihe eji arụ ọrụ na nguzogide corrosion na agba mara mma.A na-eji ọla kọpa na-acha ọcha eme ihe n'ọtụtụ ebe n'ịrụpụta ngwa ngwa enyo enyo nke ọma, igwe kemịkalụ na akụkụ ụgbọ mmiri.Ọla kọpa na-acha ọcha eletrọnịkị na-enwekarị ezigbo thermoelectric Njirimara.Ọla kọpa na-acha ọcha Manganese nwere ọdịnaya manganese dị iche iche bụ ihe eji emepụta ngwa eletriki ziri ezi rheostor precision resistance strain gauge thermocouple.

-

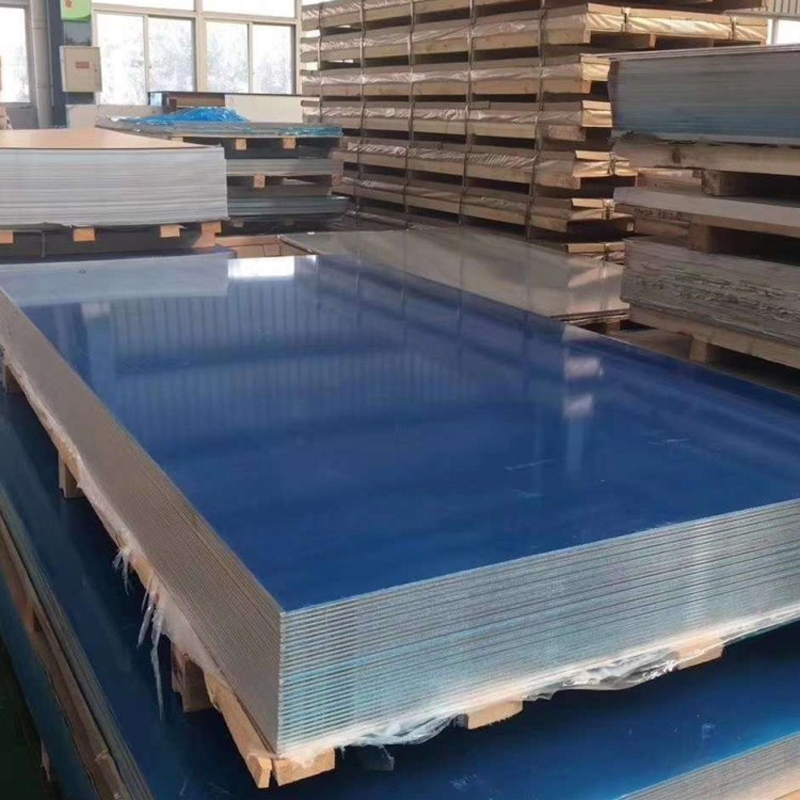

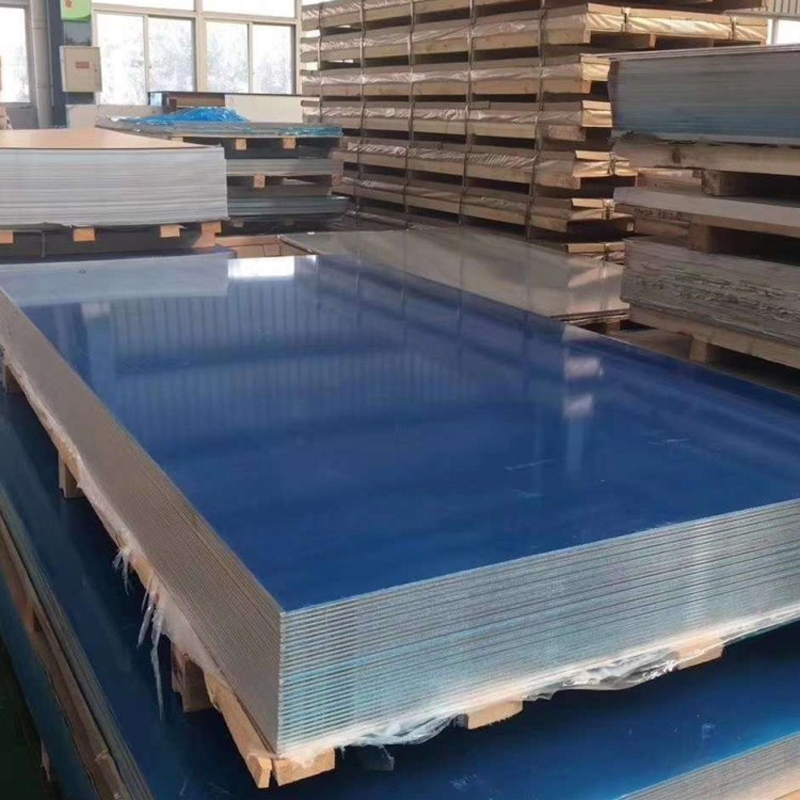

Efere Aluminom / Aluminom Alloy Plate / 7075/5052/6061

Ngosipụta ngwaahịa:

Aluminom alloy efere dị ka mkpuchi usoro nwere ike kewaa n'ime: spraying osisi ngwaahịa na pre-rola mkpuchi osisi;

Dị ka agba ụdị nwere ike kewaa: polyester, polyurethane, polyamide, gbanwetụrụ silicon, fluorocarbon, wdg.

Aluminom efere otu oyi akwa nwere ike ịbụ aluminom efere dị ọcha, manganese alloy aluminum efere na magnesium alloy aluminum efere.

Forocarbon aluminum osisi nwere fluorocarbon ịgba osisi na fluorocarbon tupu mpịakọta aluminum efere.

-

Silicon Steel eriri igwe

Ngosipụta ngwaahịa:

Silicon alloy ígwè nwere 1.0 ~ 4.5% silicon na carbon ọdịnaya erughị 0.08% na-akpọ silicon ígwè.O nwere njiri mara nke ihe ndọta magnetik dị elu, coercivity dị ala na ọnụọgụ nguzogide buru ibu, yabụ ọnwụ hysteresis na ọnwụ eddy dị ugbu a dị obere.A na-ejikarị ya dị ka ihe ndọta na moto, transformers, ngwa eletriki na ngwa eletriki.Iji gboo mkpa nke ịkụ ọkpọ na ịcha nhazi mgbe ị na-eme ngwa eletriki, a na-achọkwa plasticity ụfọdụ.Iji meziwanye ike ike ndọta ma belata nkwụsị hysteresis, na-ebelata ọdịnaya adịghị ọcha na-emerụ ahụ, nke ka mma, na ụdị efere dị larịị na ọdịdị elu dị mma.

-

304, 310S, 316, 347, 2205 Igwe anaghị agba nchara

Ngosipụta ngwaahịa:

Igwe igwe anaghị agba nchara bụ okwu n'ozuzu nke akụkụ ndị na-ejikọta, ịchịkwa, mgbanwe, ntụgharị, akara na ịkwado na usoro ọkpọkọ.Ngwakọta ọkpọkọ bụ akụkụ nke na-ejikọta ọkpọkọ n'ime ọkpọkọ.Ngwunye ọkpọkọ dị elu dabara adaba maka akụrụngwa uzuoku dị elu, kemịkalụ dị elu nke kemịkalụ na pipeline dị elu, ụlọ ọrụ ike na ụgbọ mmiri ike ọkụ nuklia, ngwa ọkụ ọkụ ọkụ ọkụ na ebe ndị ọzọ pụrụ iche.A na-eji akwa ọkpọkọ eme ihe n'ọtụtụ ebe injinia dị ka ihe owuwu, ụlọ ọrụ kemịkalụ, Ngwuputa na ume.E kwesịghị ileghara ọrụ ya dị mkpa anya.

-

Q355, P235GH, 210A1, T1, T11, T12 Round Bar Steel

Ngosipụta ngwaahịa:

Nchara gburugburu bụ ígwè siri ike cylindrical, nke nwere ike ịmepụta dayameta ya na nha dị iche iche dịka mkpa mmepụta.Usoro nhazi na-agụnye ịgbagharị ọkụ, ịse oyi, ịgha mkpụrụ na ọgwụgwọ okpomọkụ na ụzọ ndị ọzọ.N'ime ha, ịgbagharị ọkụ na-ekpo ọkụ bụ usoro a na-ejikarị eme ihe, nke nwere ike ịmepụta ígwè gburugburu na dayameta buru ibu.Usoro ịbịaru oyi nwere ike ịmepụta obere dayameta na nchara nchara dị elu.

-

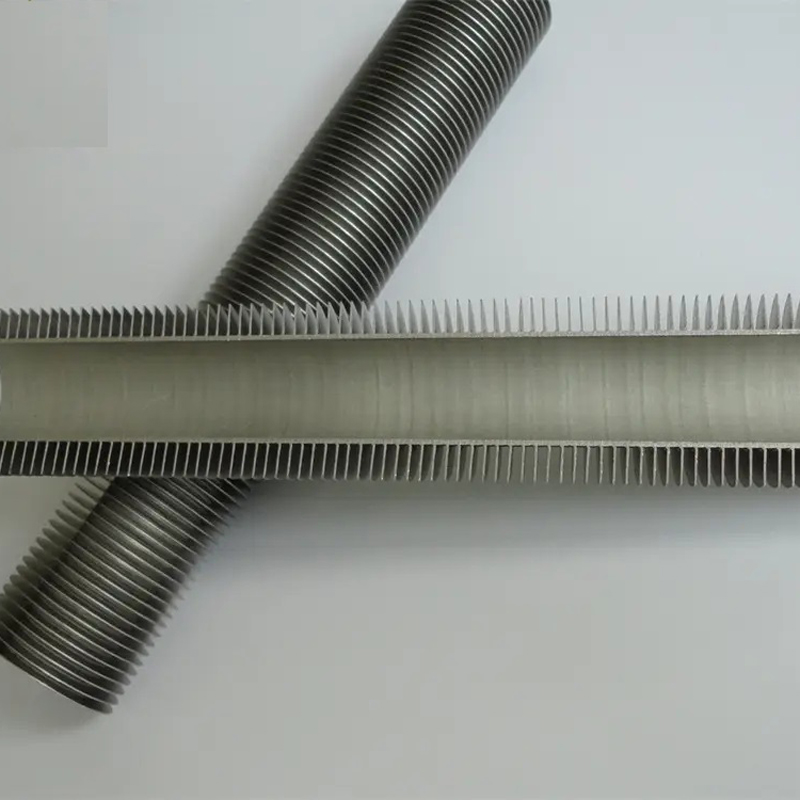

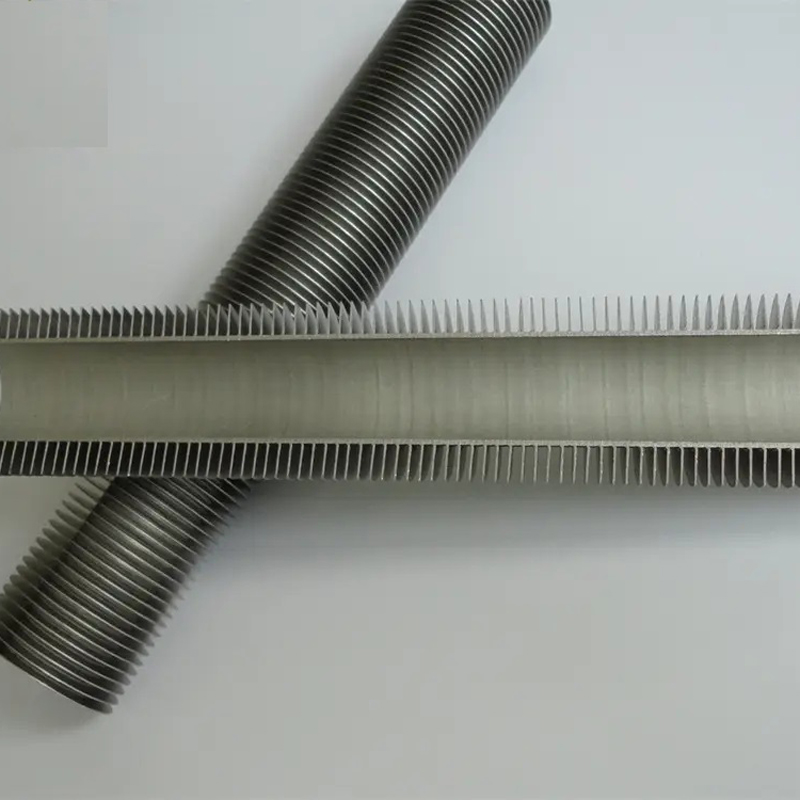

Alloy igwe anaghị agba nchara ọla kọpa Fin Tube

Ngosipụta ngwaahịa:

Akụkụ trapezoidal nke a na-emepụta site na calendering nke tube fin L na-adaba na nha nke nkesa njupụta nke okpomọkụ na-asọba, na akụkụ ahụ jikọtara ọnụ na arụmọrụ okpomọkụ dị elu, nke na-ewepụ kọntaktị thermal resistance nke akụkụ ahụ kpatara. oghere.

Ọnọdụ okpomọkụ: 230 ℃

Njirimara: ojiji nke usoro ikuku, nrụpụta mmepụta dị elu, ịdị anya otu, nnyefe ọkụ dị mma, oke nku dị elu, enwere ike ichebe isi tube site na mmebi ikuku.

Ngwa: tumadi ji petrochemical, electric ike, akwụkwọ, ụtaba, ụlọ kpo oku na ndị ọzọ na ọrụ nke ikuku oyi, ikuku okpomọkụ na nri ụlọ ọrụ osisi protein ntụ ntụ, starch na ndị ọzọ ịgba ihicha usoro nke ikuku kpo oku.