SA588 SA387 Alloy Steel efere

Mmetụta nke ihe ndị na-emepụta ihe na nhazi usoro nke ígwè

1. Mmetụta nke ihe alloy na-arụ ọrụ nkedo ígwè

Na-ebelata okpomọkụ nke ahịrị usoro nke siri ike na nke mmiri mmiri na ebe okpomọkụ kristal na-adịwanye njọ, otú ahụ ka arụmọrụ nkedo ahụ ka mma.Mmetụta nke ihe alloy na arụmọrụ nkedo na-adabere karịsịa na mmetụta ha na eserese oge Fe-Fe3C.Na mgbakwunye, ọtụtụ ihe, dị ka Cr, Mo, V, Ti, Al, na-etolite nnukwu agbaze carbide ma ọ bụ oxide particles na ígwè, nke na-eme ka viscosity nke ígwè dị elu, na-ebelata mmiri mmiri, na-emebi ọrụ nkedo.

2. Mmetụta nke ihe ndị na-emepụta ihe na plastik machining nke ígwè

A na-ekewa nhazi plastik na nhazi okpomọkụ na nhazi oyi.Alloy ọcha n'ime ngwọta siri ike, ma ọ bụ nguzobe nke carbide (dị ka Cr, Mo, W, wdg), melite thermal deformation nguzogide nke ígwè na ịrịba ọdịda nke thermoplasticity na mfe forge na mgbape.The thermal nhazi usoro arụmọrụ nke general alloy ígwè dị nnọọ njọ karịa nke carbon ígwè.

3. Mmetụta nke ihe ndị na-emepụta ihe na ihe ndị na-agbado ọkụ nke ígwè

Alloy ọcha niile na-eme ka quenability nke ígwè, na-akwalite guzobe nke kenkuwa anụ ahụ (martensite), na-eme ka ịgbado ọkụ arụmọrụ ka njọ.Otú ọ dị, ígwè ahụ nwere obere Ti na V, nke nwere ike imeziwanye ọrụ ịgbado ọkụ nke ígwè.

4. Mmetụta nke ihe ndị na-eme ihe na-eme ka ọkpụkpụ na-arụ ọrụ nke ọma na-arụ ọrụ nke ọma na-ejikọta ya na ike nke ígwè, ígwè dị mma maka ịcha nhazi nhazi nke 170 HB ~ 230 HB.Mbelata arụmọrụ nke nchara nchara n'ozuzu dị njọ karịa nke carbon ígwè.Otú ọ dị, mgbakwunye kwesịrị ekwesị nke S, P, Pb na ihe ndị ọzọ nwere ike ime ka ọkpụkpụ ígwè dịkwuo mma.

5. Mmetụta nke ihe alloy na-arụ ọrụ nke usoro ọgwụgwọ okpomọkụ nke ígwè

Ịrụ ọrụ nke usoro ọgwụgwọ okpomọkụ na-egosipụta ihe isi ike nke ọgwụgwọ okpomọkụ ígwè na ọchịchọ nke ọgwụgwọ okpomọkụ.Ọ na-agụnyekarị ike ọgwụgwụ, oke ekpo oke ọkụ, mgbakasị ahụ ọkụ na oxidative decarbonization.Alloy ígwè nwere nnukwu quenability, na a dịtụ nwayọọ nwayọọ usoro nwere ike iji mgbe quenching, nke nwere ike ibelata deformation na cracking ọchịchọ nke workpiece.Ịtinye manganese na silicon ga-eme ka mmetụta ọkụ na-ekpo ọkụ nke ígwè ahụ dịkwuo elu.

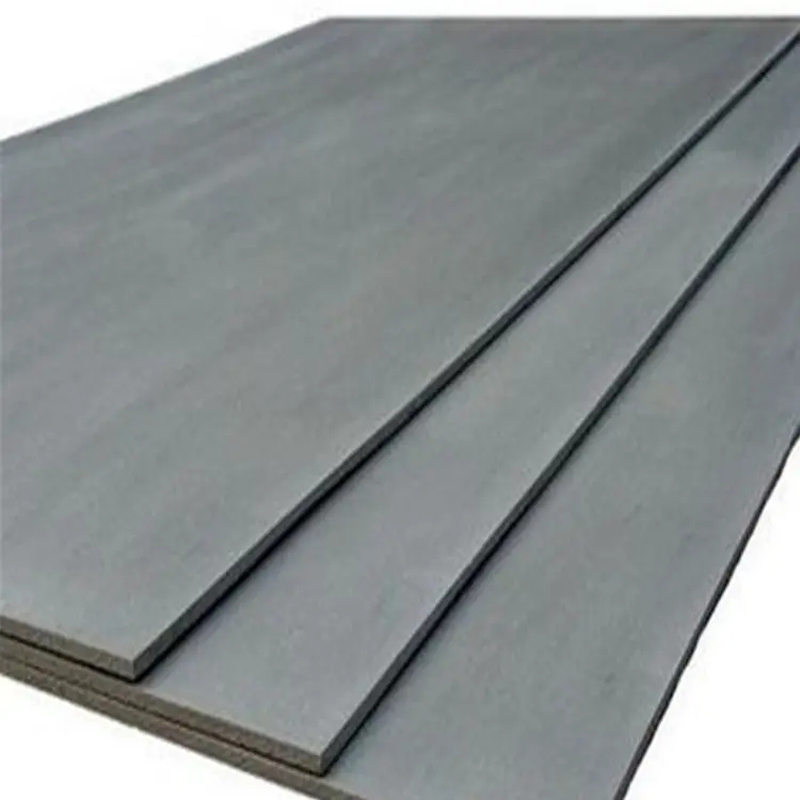

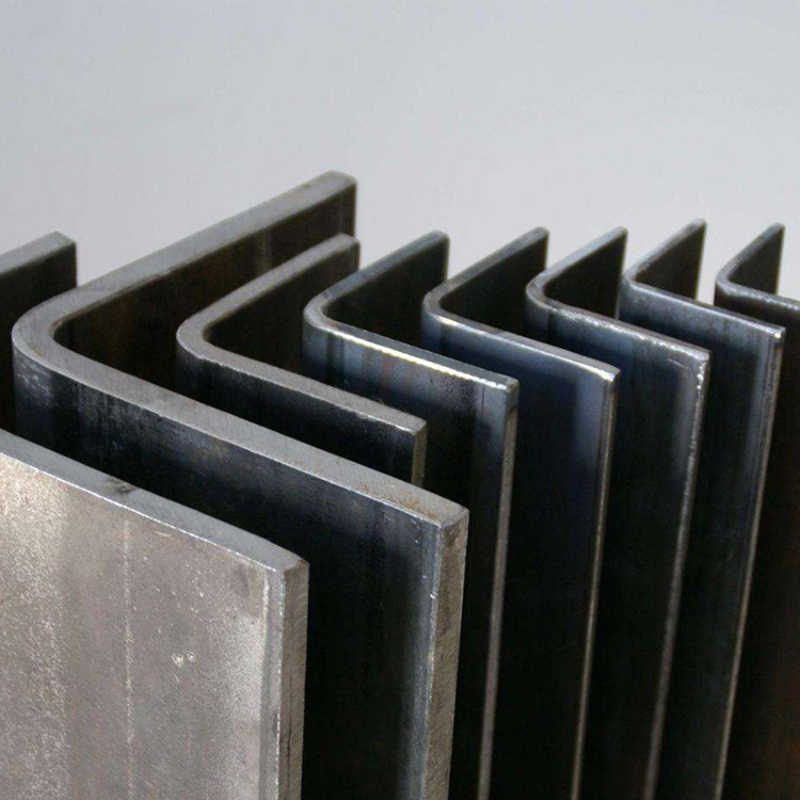

Nkọwa ngwaahịa

| Ọkwa igwe: | 15CrMo, 12CrMoV, EN: S235JR, S275JR, S355JR, S420NL, S460NL, S500Q, S550Q, S620Q, S690Q ASTM: Ọkwa B, Ọkwa C, Ọkwa D, A36, Ọkwa 36, Ọkwa 40, Ọkwa 42, Ọkwa 50, Ọkwa 55, Ọkwa 60, Ọkwa 65, Ọkwa 70, Ọkwa JIS: SPHC, SS400, SPFC, SPHD, SPHE |

| Ọkọlọtọ: | DIN EN 10083, ASME SA516, ASTM A203M, ASME SA588, ASME SA387, SAE1045 JIS G4051,AISI, BS |

| Ọkpụrụkpụ: | 1.0-300mm |

| Obosara | 100-4500mm, ma ọ bụ dị ka ndị ahịa pụrụ iche arịrịọ |

| Ogologo: | 1-20meters, ma ọ bụ dị ka ndị ahịa pụrụ iche arịrịọ |

| ngwugwu: | Ngwugwu ọkọlọtọ mbupụ |

| Ngwa: | 1.Machinery, Ụlọ ọrụ arịa nrụgide. 2. Ụgbọ mmiri na-ewu ụlọ, Injinia na-arụ ọrụ. 3.Utomobile, Bridges, Ụlọ. 4.Mechanical n'ichepụta, Pavement slab, ect. |

| Mill MTC: | Ebutere tupu mbupu |

| Nyocha: | Enwere ike ịnakwere nyocha nke atọ, SGS, BV, TUV |

| Ugwu Port: | Ọdụ ụgbọ mmiri ọ bụla na China |

| Oge ahia ahia: | FOB, CIF, CFR, EXW, wdg. |

| Oge ọnụahịa: | TT ma ọ bụ LC na anya |

| Ọrụ anyị: | Anyị nwere ike bee na ehulata ígwè efere dị ka ndị ahịa requrement ma ọ bụ ịbịaru, nkwakọ dị ka ndị ahịa' arịrịọ |

Ihe ngosi ụlọ ọrụ